1. Manual Powder Coating Machine Overview

A Manual Powder Coating Machine is a portable handheld system ideal for small-scale or precision work. Key components include a spray gun with an electrostatic generator (20–100 kV) a powder hopper (1–5 kg capacity) and a compressed air supply (40–80 PSI). Basic models use gravity-fed guns while advanced versions feature fluidized beds for consistent powder flow.

2. Applications of Manual Powder Coating Machines

Perfect for coating small metal parts like bicycle frames automotive brackets or DIY furniture. Hobbyists repair shops and artisans use manual machines for low-volume jobs touch-ups or intricate designs requiring detailed control.

3. Manual Powder Coating Machine Price Range

Entry-level kits: 200–500 (basic spray gun air compressor not included).

Mid-range setups: 600–1,500 (fluidized bed guns adjustable voltage).

Professional-grade systems: 2,000–5,000 (high-precision guns with digital controls).

Costs are 80–90% lower than automated systems making manual machines ideal for startups.

4. How to Use a Manual Powder Coating Machine

Ground the workpiece and gun to prevent static discharge.

Maintain a 6–10 inch distance from the target for even coverage.

Adjust voltage (30–70 kV) based on part size and powder type.

Clean the gun nozzle after each use to avoid clogs.

5. Choosing the Right Manual Powder Coating Machine

Gun type: Opt for fluidized bed designs for complex shapes.

Portability: Lightweight models (under 5 lbs) suit mobile projects.

Powder compatibility: Ensure the gun works with epoxy polyester or hybrid powders.

Air supply: Verify compressor compatibility (CFM requirements).

6. Safety Tips for Manual Powder Coating Machine

Wear an N95 mask and gloves to avoid inhaling particles.

Work in a ventilated area or use a DIY spray booth.

Avoid spraying near flammable materials.

Regularly inspect gun cables for wear or damage.

7. Pros and Cons of Manual Powder Coating Machines

Pros: Low cost easy maintenance and flexibility for detailed work.

Cons: Slower than automated systems higher skill requirement and limited batch capacity. Ideal for projects under 50 parts per day.

8. Manual Powder Coating Machine FAQs

Q1 Can manual machines coat large surfaces

A Yes but multiple passes are needed for uniformity.

Q2 How to clean a manual powder coating gun

A Disassemble and blow out residue with compressed air.

Q3 What powders work best with manual systems

A Fine-grained powders (25–45 microns) ensure smooth application.

Q4 Are manual machines energy-efficient

A Yes most consume under 500 watts per hour.

Q5 How to reduce overspray in manual coating

A Use a grounded spray booth and maintain proper gun distance.

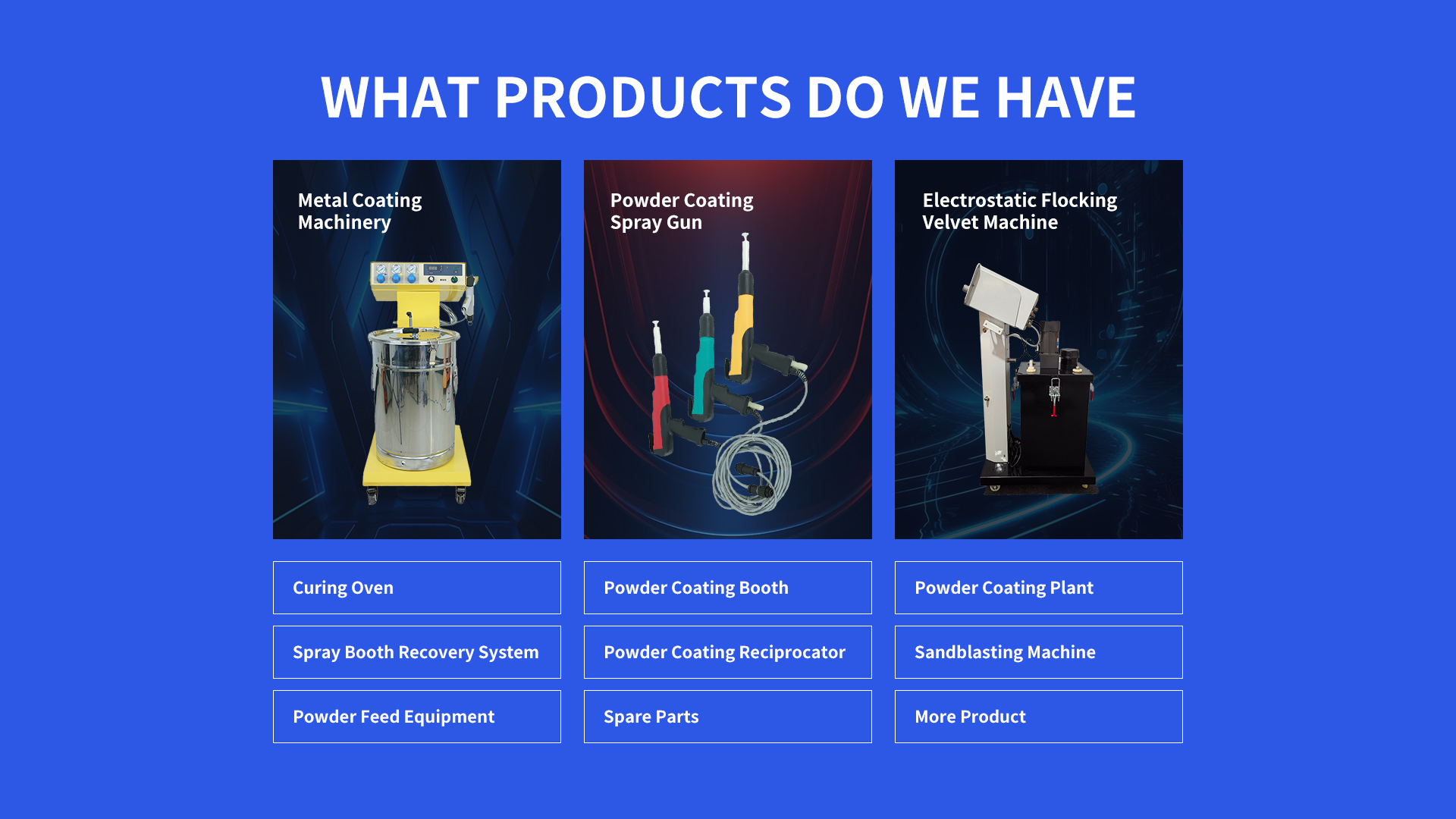

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com